Low Volume Injection Molding offer you quick turnaround times and cost-effective solutions for your small-scale plastic componets production runs

What is on-demand manufacturing?

On-demand is a relatively new concept in manufacturing. It enables manufacturing low-volume, customized products when needed and ordered. While traditional manufacturing involves mass production of similar products.

This approach is ideal for companies seeking to reduce inventory, respond quickly to market changes, and offer tailored. Three popular technologies for on-demand, low-volume manufacturing are injection molding; 3D printing, and CNC machining.

Customized production

On-demand manufacturing

Manufacturing Processing

Why low-volume manufacturing is important?

- Tailored solutions: Low-volume production allows for customized products tailored to specific customer needs and preferences. This ensures greater customer satisfaction.

- Cost efficiency and niche markets : By producing smaller batches of products, manufacturers can avoid the high setup costs associated with large-scale production. This cost-effectiveness is particularly beneficial for niche markets or specialized products with limited demand.

- Flexibility and agility: Low-volume production offers greater flexibility and agility in responding to changing market demands and customer requirements. That allows the manufacturer make response quickly to adjust the production schedule and product specifications. That helps avoid the excessive inventory and long lead times.

- Market testing and innovation: It offers the chance to try out new products or variations in the market without having to commit to large production runs. This allows for rapid prototyping, iteration and innovation, minimizing the risks associated with bringing new products to market.

- Risk mitigation in new product launches: Launching a new product carries risks, particularly when it comes to how it will be received in the market. Low-volume manufacturing allows you to produce smaller batches to test the water and the response of the marketing. That reduced the potential financial impact if the new product doesn’t perform as expected.

- Reduced inventory cost: since low-volume manufacturing refers to producing smaller quantities, it helps minimize inventory costs. This leads to improved cash flow management and reduces the potential risk of outdated storage.

- Shorter lead time: Low-volume production, typically involving quantities in the hundreds or thousands, allows manufacturers to reduce lead times, making the deliver faster and enter the market earlier with new products.

- Sustainability and reduced waste: low-volume manufacturing process offers environmental benefits by reducing waste and energy consumption compared to mass production

What Is the Cost-Benefit Analysis: Low vs. High-Volume Production?

| Aspect | Low-Volume Production | High-Volume Production |

|---|---|---|

| Costs | ||

| Per-unit production costs | Higher due to limited economies of scale | Lower due to economies of scale |

| Setup costs | Proportionally higher due to spread over smaller runs | Amortized over larger runs, reducing cost per unit |

| Economies of scale | Limited due to smaller production quantities | Realized, leading to cost savings on materials and labor |

| Labor costs | Potentially higher due to less efficient processes | Potentially lower due to optimized processes and automation |

| Benefits | ||

| Customization opportunities | Tailoring products to specific customer needs | Limited by standardized production processes |

| Inventory costs | Reduced due to smaller production runs | Higher risk of excess inventory and holding costs |

| Flexibility and agility | Quick response to market changes and customer demands | Less flexibility due to longer production cycles |

| Innovation and market testing | Lower risk experimentation with new products or variations | Limited by higher investment and production commitment |

| Financial | ||

| Initial investment | Lower investment required | Higher upfront investment in equipment and facilities |

| Profit margins | Potentially lower due to higher production costs | Potentially higher due to lower production costs |

| Production Efficiency | ||

| Production output | Limited by production capacity and setup constraints | Optimized with higher output and lower unit costs |

| Product availability | Limited availability due to smaller runs | Consistent availability to meet market demand |

Conclusion:

Understanding Production Costs: Low-Volume vs. High-Volume

Low-Volume Production:

This will lead the higher cost for each unit because it doesn’t benefit from mass production. This tends to result in a result in a higher setup cost and also a chance to get a higher labor cost for each product. However, low-volume production involves less initial investment and reduces the risk of excessive inventory. and it also offers an agile response to market trends and a favorable environment for testing new product concepts at a lower financial risk.

High-Volume Production:

On the flip side, high-volume production is marked by its cost-saving nature, particularly when it comes to the cost of each item, thanks to the advantages of producing in large quantities. The more you make, the less you spend on setup per item, and often, the labor cost per product drops as well due to streamlined and automated processes. Although starting a high-volume production run requires more money upfront, it ultimately drives down the cost of each product over time and can lead to savings through bulk buying. However, it does come with its own set of risks, such as potentially having excessive stock and being slower to adapt to new market conditions.

Making the Decision:

Deciding between low and high-volume production isn’t just about counting costs — it’s about aligning your production strategy with your company’s market positioning, financial considerations, and the need to balance cost-effectiveness with the ability to quickly meet market demands. Each business will need to evaluate these factors to determine the most suitable production path.

What benefits do low-volume injection moldings provide?

Injection molding is one of the primary processes for rapid manufacturing. It’s a rapidly evolving model that can expedite time to market. However, the traditional process isn’t as swift as desired in certain aspects. The demand in the plastic market sometimes contradicts the nature of production. The complexity of mold design can further elongate the time required for manufacturing parts. Nonetheless, low-volume injection molding helps effectively address these issues. Here are some advantages:

Key Advantages:

- Aluminum Tooling Over Steel: Low-volume injection molding utilizes aluminum molds instead of traditional hardened steel molds. Aluminum is softer and allows for easier and quicker mold fabrication. It also simplifies heat treatment without requiring additional annealing steps, while still supporting various surface treatments

- Manufacture of High-Quality Parts: Despite using softer mold materials, low-volume injection molding can still produce highly durable and functional parts. It’s a practical manufacturing technique for producing various types of products.

Additionally, aluminum possesses better thermal conductivity compared to steel. Better conductivity makes the positioning of cooling lines less critical. Thus, there’s more space for mold components.

Therefore, low-volume injection molding ensures better design flexibility, narrowing the gap between prototyping and mass production.

Cost Savings: The ability to manufacture without exorbitant overheads or minimum order quantities translates to significant cost savings.

- Swift Turnaround:The streamlined production cycle, courtesy of aluminum’s malleability and optimized quoting systems, accelerates time-to-market.

- Design Versatility: The agility of small-scale production allows for rapid implementation of design changes, ensuring the final product is finely tuned.

The Digital Backbone: Real-Time Quotes and Order Monitoring:

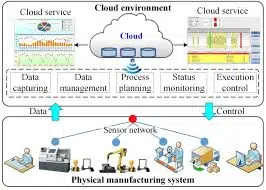

At the heart of on-demand manufacturing lies a digital spine that supports real-time quotes and meticulous tracking of the manufacturing process. This transparent interface between engineers and suppliers is a game-changer, instilling confidence and clarity in the production journey.

Digital Integration:

- The self-service model central to on-demand manufacturing is facilitated by cloud-based platforms that ensure a seamless customer experience.

- Real-time analytics and monitoring tools provide customers with up-to-the-minute updates, engendering trust and fostering a partnership ethos in manufacturing.

Conclusion: Embracing the Manufacturing Revolution:

As we stand on the cusp of a new era in manufacturing, it’s clear that on-demand, low-volume production is not just a passing phase—it’s the vanguard of an industrial metamorphosis. With its focus on sustainability, efficiency, and customization, it’s poised to shape the future of manufacturing for years to come.

FAQs:

On-demand, low-volume manufacturing is a production approach that enables the creation of small batches of custom parts. It's driven by customer demand, offering flexibility, quick turnarounds, and reduced waste.

Unlike mass production, which focuses on large volumes to reduce cost per unit, on-demand manufacturing emphasizes personalized, low-volume batches, using digital technologies to streamline the process.

Aluminum tools are faster to create and don't require hardening, which shortens lead times and reduces costs, while still producing high-quality, functional parts.

Yes, by avoiding large upfront investments in tooling and mitigating the need for large inventories, on-demand manufacturing can result in significant cost savings.

Due to the efficiency of tooling and the streamlined quoting process, delivery times are greatly reduced, facilitating a quicker time to market.

Design flexibility allows for adjustments to be made in response to feedback or market changes without significant cost or time penalties.

Digital technology enables real-time quotes, design validation, and order tracking, which enhances the manufacturing process by making it more transparent and efficient.

Real-time monitoring provides customers with visibility and control over their orders, improving trust and satisfaction by keeping them informed at every step.

Yes, it aligns with sustainable practices by reducing waste and energy consumption through demand-driven production and shorter supply chains.

Low-volume manufacturing allows for iterative design and testing, ensuring that the product is market-ready before scaling up to mass production.