What are CNC metal milling machines, and how do they work?

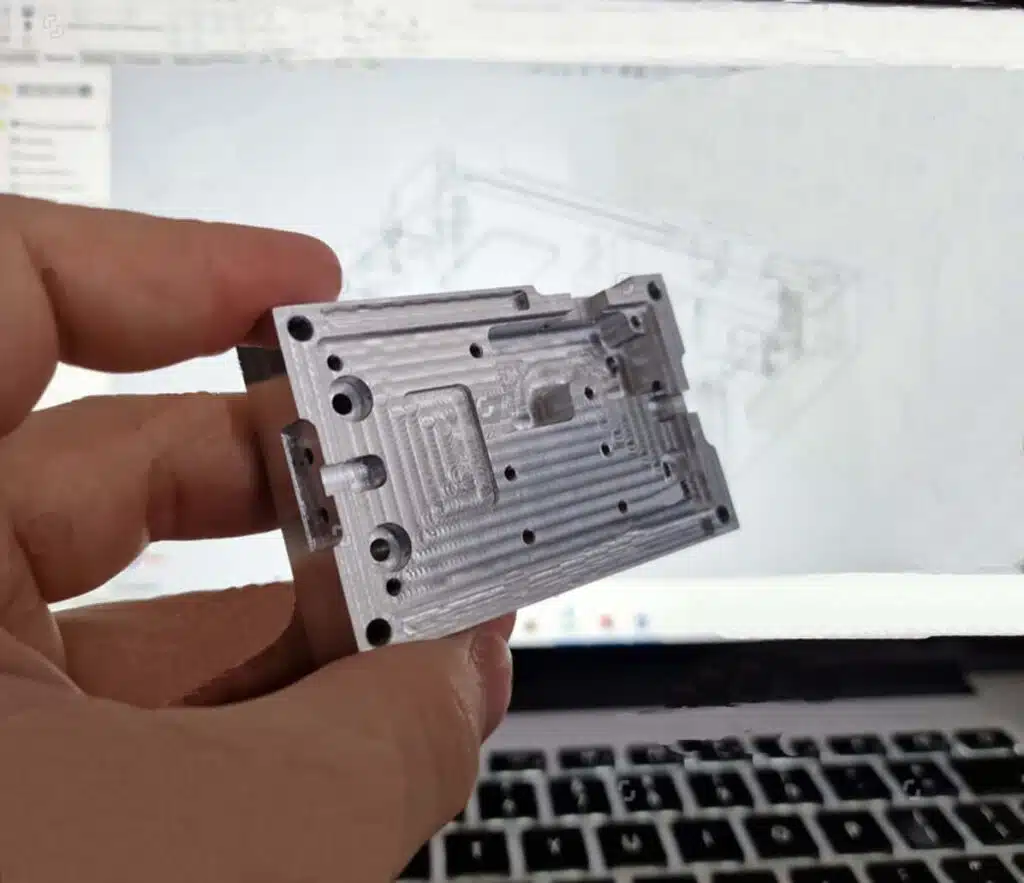

CNC metal milling machines are machinery that uses computer program controls precisely to shape metal into components. These machines offer exceptional precision and accuracy, enabling the production of complex components with tight tolerances.

CNC metal milling machines play an important role in CNC machining processing.

What are the advantages of using CNC metal milling for manufacturing?

- Precision and accuracy: CNC metal milling machines are highly accurate and can produce tight-tolerance parts.

- Consistency: CNC milling operates under programmed instructions, ensuring consistent quality and speed throughout the process.

- Complex Geometry: CNC milling can produce parts with intricate shapes and complex geometries. This allows for design flexibility and innovation.

- Versability in Operations: CNC milling machines can perform a many manufacturing operations, including boring, drilling, thread cutting, broaching, and milling.

- Material: capable of working with various materials, from soft plastic to hard titanium alloy.

- Save cost: CNC milling is entirely automated; this reduces labor costs and minimizes the risk of errors caused by humans.

- Fast Prototyping: The high efficiency of CNC milling speeds up the new product launch, detects the design flaws on time, and optimizes the design promptly.

- Increased Production Efficiency: CNC milling machines operate with consistency 24/7, resulting in shorter lead times.

AMSL’s Cutting-Edge CNC Metal Milling Services

AMSL offers a range of CNC metal milling services with detailed specifications and customized options.

- MAKINO F5 Milling: High precision and speed.

- High-Speed Engraving and Milling Series MK-540D: Ideal for smaller workpieces.

AMSL CNC milling machine’s parameter

| Machinery Model# | Spindle Speed( rpm) | Max Workpiece(mm) | Tolerance(mm) | Quantity( Sets) |

|---|---|---|---|---|

| MAKINO F5 | 20000 | 1000*500*450 | ±0.001mm | 2 |

| MK-540D | 15000 | 500*450 | ±0.005mm | 18 |

| KIRA PC-30W | 15000 | 500*350 | ±0.005mm | 1 |

AMSL’s Tailored CNC Metal Milling Services

Fast Prototype development: AMSL provides tailored prototyping services. Send us your design and requirements; we will provide samples within 3-7 days.

Low-volume production runs: AMSL provides you with one of the most significant benefits: no MOQ. This means we can efficiently manufacture low-volume parts and even one-off customized products.

High-volume production runs: At AMSL, our 21 sets of CNC milling machines always get ready to handle high-volume production with precision and efficiency. You can rely on us to meet your manufacturing needs with ease.

Fast Delivery: 24/7 work hours, ensure timely delivery.

Reverse/backward engineering: AMSL engineers start by analyzing a target part backward to obtain detailed CAD models.

Various Surface Treatment: AMSL provides a range of surface treatment options tailored to material types and specific customer needs. Our standard finishing techniques include anodizing, plating, powder coating, painting, and polishing.

Free guide on how to choose cutting tools for the milling process?

Content:

- What materials can be CNC milled?

- How do you choose the cutting tool’s speed and width?

- What’s the material for the common types of milling cutters?

- How does CNC metal milling differ from traditional milling methods?

- What industries benefit the most from CNC metal milling?

- How can CNC metal milling contribute to cost savings in manufacturing processes?

- What are the best CNC milling machines for beginners?

- What surface can a CNC milling machine?

FAQs: common questions about CNC metal milling.

What materials can be CNC milled?

CNC milling is a versatile process capable of working with a wide range of materials, including:

- Metals: Aluminum alloy, brass, steel, titanium alloy

- Plastics: Acrylic, polycarbonate, nylon

- Others: Wood, foam, ceramics, composites

No matter soft or rigid material, a CNC milling machine can shape and mill them accurately.

What’s the material for the common types of milling cutters?

Milling cutter is a common cutting tool on metal cutting machines, so the quality of the milling cutter material directly affects the efficiency and quality of the milling process. The following are the common types of milling cutter materials:

High-speed steel (HSS): High-temperature resistance, long-lasting sharp edge, good overall performance. HSS is suitable for high-temperature alloy, titanium alloy, super-strength steel, etc.

Carbide ( WC): High density, high hardness, poor toughness, suitable for milling deep grooves and processing hard materials.

Ceramics: Offer high heat and wear resistance, suitable for superalloys and hardened steels.

Diamond: Diamond has extremely high hardness and wear resistance and can be used for machining rigid materials such as ceramics, glass, and composites.

PCD ( Polycrystalline cemented carbide ): Low density, high -hardness, high wear resistance, suitable for milling materials such as aluminum and copper.

CBN (Cubic boron nitride): Low density, good thermal stability, excellent cutting performance. Suitable for milling high-hardness materials and stainless steel.

What industries benefit the most from CNC metal milling?

- Aircraft/Military Manufacturing: Components like motors, brackets, and reinforcement plates demand CNC milling for high precision, strength, and corrosion resistance.

- Automotive Industry: CNC milling can produce engine bases, transmission axles, and steering gears, with high precision and stability.

- Mold Making: CNC milling is essential for manufacturing complex and curved surfaces in molds.

What is the best CNC Milling machines for the beginner?

- SainSmart Genmitsu CNC Router Machine: This desktop CNC milling machine is affordable and suitable for beginners and hobbyists.

- BobsCNC E3 CNC Router Engraver Kit: A budget-friendly option for those looking to start with CNC milling and engraving projects.

- Proxxon 37110 Micro Mill MF 70: This type of micro-milling machine is compact and cost-effective, an ideal choice for small-scale projects and precision work.

- Sherline 5400 Deluxe Vertical Milling Machine: A versatile and cost-effective option for beginners and hobbyists.

The CNC milling machines above are affordable and perform well; they are the best choice for beginners.

How to choose the cutting tool’s speed and width?

- Optimal Tool Selection: Choose carbide end mills or tools that don’t need regrinding for surface milling. During general milling operations, aim for two passes. Use an end mill for rough milling in the first pass, then continue passing along the workpiece surface. Ideally, each pass should be 60% to 75% of the tool’s width diameter.

- Tailored Tool application: Apply end mill and carbide blade end mill for processing bosses, grooves, and box mouth surface.

- Processing curved surfaces: The round ball nose mill cutter is for curved surfaces and variable contours.

ball nose milling cutters are for finishing

round nose milling cutters with carbide inserts are for rough machining.

How does CNC metal milling differ from traditional milling methods?

- Different operation methods: Traditional milling mainly relies on manual operations such as tool changes, processing monitoring, etc. While computer programs control the CNC milling.

- Different efficiency: CNC milling is highly efficient in manufacturing due to its automation. Operators input programs into the computer, which then controls operations like monitoring and tool changes.

- Different precision: Manually performing the traditional milling has the risk of causing errors.

- Function different: A CNC mill can manufacture complex parts with various shapes or surfaces. However, traditional milling is only for flat surfaces.

How can CNC metal milling contribute to cost savings in manufacturing processes?

- Increased efficiency: This benefits from its automated operation; after setting up the parameters and input programs, it performs 24/7.

- Improved precision: A CNC metal mill is computer-controlled machinery that performs according to program instructions. Compared to manual milling, CNC milling minimizes errors and material wastage.

- Saved labor cost: Since CNC milling is automated, it requires fewer manual operations, which leads to reduced labor expenses.

What surface can CNC milling machined?

Plane type parts: including positive, negative, oblique plane surfaces

Curved surface components: including spherical, conical, inclined surfaces,etc.

Variable beveled parts: Such as the whole beam, frame, edge strips and ribs on the airplane, etc.

Get Your CNC Milling Project Started Today

Whether you’re prototyping or mass production, Just send your 3D CAD file—the blueprint for your project.

© 2024 All Rights Reserved.