In 2022, CRRC shocked engineers worldwide with train bearings accurate to 0.01mm – thinner than a human hair. This breakthrough showcases China’s new role: the world’s workshop for precision manufacturing solutions.

Key Stats:

✔️ Fortune 500 Adoption: 73% now source precision components from Chinese suppliers (WEF Report), driven by:

~40% cost savings vs. US/EU manufacturers

15-day average turnaround for complex geometries

⚡ Operational Benchmark: iPhone frame production hits 99.8% yield rates—outperforming Western quality thresholds.

3 Technologies Redefining Manufacturing

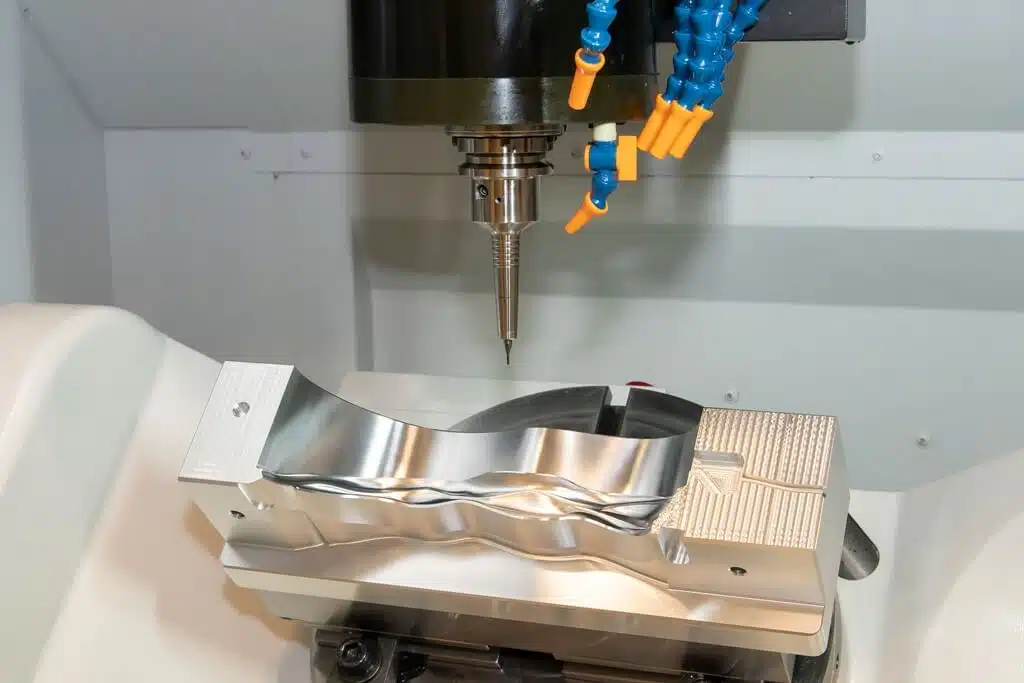

1. CNC Machining: Precision Meets Speed

What It Solves: Creating complex metal/plastic parts with ultra-tight tolerances

China’s Edge:

- Military-Grade Accuracy: 0.8μm precision for missile components

- EV Innovation: BYD’s battery trays with 0.02mm flatness

- Smart Factories: AI-powered QC cuts defects by 55%

Best For: Aerospace brackets, medical implants, automotive prototypes

2. Injection Molding: Mass Production Perfected

What It Solves: High-volume plastic parts with perfect consistency

China’s Breakthroughs

✅ Sustainable Tech Leap: All-electric molding systems slash energy use by 40% while delivering:

- Bio-degradable polymers for automotive/medical applications

- Zero-defect precision at Apple-certified standards

- 🚀 Speed Meets Scale: From prototyping to mass production, timelines compressed by 65% vs. traditional supply chains.

Ideal For: Consumer electronics, medical devices, automotive interiors

3. EDM (Electrical Discharge Machining): The Detail Specialist

What It Solves: Cutting hardened metals into intricate shapes

China’s Expertise:

- Coronary stent molds with 1.2μm finish

- 30% faster die production for EV motors

- Titanium aerospace parts with ±2μm accuracy

Perfect For: Surgical tools, automotive dies, turbine blades

China vs. Global Competitors: Cost & Speed Comparison

| Factor | China | Germany | USA |

|---|---|---|---|

| Hourly Labor Cost | $6–9 | $40–55 | $35–50 |

| CNC Cost/kg (Aluminum) | $18–25 | $55–75 | $60–80 |

| Mold Lead Time | 15–20 days | 45–60 days | 30–40 days |

Source: 2023 UNIDO Manufacturing Report

5 Questions Global Buyers Ask

- Are Chinese factories truly ISO-certified?

Yes – 12 major CNC brands meet ISO 13399 standards, with 89% using German/Japanese QC systems. - How to ensure quality from overseas suppliers?

- Demand third-party inspection reports

- Start with small prototype orders

3. What materials can Chinese shops handle?

From aerospace aluminum (7075-T6) to PEEK medical plastics.

4. Minimum order quantities (MOQs)?

As low as 1 unit for CNC, 500+ for molding.

5. Shipping times to Europe/US?

7–10 days by air, 25–35 days by sea.

Future Trends in Chinese Precision Manufacturing

- AI-Powered Factories: Real-time error detection during machining

- Hybrid 3D Printing/CNC: 6-week lead times for jet engine parts → 6 days

- Green Manufacturing: Solar-powered CNC hubs in Guangdong

How to Start Working With Chinese Suppliers

- Define Your Requirements

- Tolerance needs (standard: ±0.1mm, high-precision: ±0.01mm)

- Specify materials /Certification (e.g., brand or models)

- Surface finishing(types/ coating thickness)

2. Sample Process

Prototype (200-800) → Testing → Full Production

Partner with AMSL: Your Precision Manufacturing Solutions Expert

With 10+ years in CNC machining and injection molding, AMSL delivers:

- CNC machined components with ±0.005mm tolerances

- Medical device molds compliant with ISO 13485 standard

Why AMSL?

- 0.08% defect rate (industry average: 0.35%)

- 12-day average CNC machining lead time, 48 hours for prototyping samples.