What are brass fasteners?

Brass fasteners, made from a copper-zinc alloy, are used to join components. They are popular for their corrosion resistance, strength, ease of machining, and attractive appearance. This guide covers the types of brass fasteners, their benefits, common uses, and tips for selection and maintenance.

Types of Brass Fasteners & Their Definitions

Brass Fasteners Overview

Brass fasteners are essential in various industries, offering strength, durability, and corrosion resistance. Understanding the different types available is crucial for effective use in specific applications.

1. Copper Nuts and Bolts

Nuts: Fasteners with internal threads by screwing onto a bolt.

Bolts: Threaded fasteners with a smooth cylindrical shaft, used to connect two through-hole components. They are often paired with nuts. But the nut also can detach from the bolt, making the bolt connections removable.

2. Screws and Washers

Screws: Fasteners with a helical ridge thread) design, drive into the material to hold components together. They come in various types, including machine screws, set screws, wood screws, and self-tapping screws.

Washers: Flat, circular components placed under the head of a screw or nut to distribute the load, reduce vibration, or prevent loosening.

3. Studs

Studs are threaded fasteners without heads and are installed directly into a component. They provide a base for securing nuts or other attachments. Studs are commonly for creating a permanent threaded connection.

4. Self-Tapping Screws

They are a type of screw that cuts their threads into a material as they are driven in. They are useful for creating threads in materials without pre-drilling.

5. Wood Screws

Screws specifically designed for use in wood. They have coarse threads that provide a strong grip on wood fibers.

6. Retaining Rings

Circular rings are for securing components onto shafts or in housings, preventing axial movement. They come in internal and external types, depending on the application.

7. Pins

Cylindrical fasteners are for securing parts together or aligning components. They come in various forms, including dowel pins, cotter pins, and roll pins.

8. Rivets

Rivets are permanent fasteners for joining parts by deforming the end after insertion. They’re commonly used in metalworking.

9. Fastener Assemblies and Connecting Parts

Pre-assembled sets of fasteners, such as nuts, bolts, and washers, are designed to simplify assembly and ensure compatibility.

Connecting Parts: To link or join different parts, which may include various types of fasteners and connectors.

10. Others (e.g., Welding Nails, Shaped Nails, Screw Plugs, etc.)

a. Welding Nails.: Fasteners used in welding applications to join metal parts together. Typically we use them in construction and metal fabrication.

b. Shaped Nails: Nails with specific shapes or profiles to provide a particular type of hold or to fit certain applications.

c. Screw Plugs: A type of fastener to plug or seal threaded holes. They secure holes efficiently, preventing dirt and debris from entering while giving a polished look.

With its diverse types and functions, Brass fasteners cater to various connection needs. Therefore, selecting the right fastener ensures performance and reliability in any application. and staying updated on the latest trends will be crucial for future developments.

Advantages of Brass Fasteners

Corrosion Resistance

Initially, brass fasteners excel in resisting rust and corrosion compared to steel counterparts. This makes them ideal for use in harsh environments, such as marine and outdoor applications.

High Strength and Durability

Secondly, it provides excellent strength and durability, ensuring long-lasting performance in demanding applications. The alloy’s combination of copper and zinc offers superior tensile strength compared to pure copper.

Good Conductivity

Brass is an excellent conductor of electricity and heat, making brass fasteners suitable for electrical and thermal applications.

Aesthetic Appeal and Machinability

Additionally, the gold-like appearance makes it an attractive choice for decorative applications. Additionally, due to the soft feature brass is relatively easy to machine, allowing for precise cutting, drilling, and shaping custom-made fasteners.

Applications of Brass Fasteners

Construction and Remodeling

For instance, in construction, brass fasteners are used for fixtures, fittings, and hardware. Their corrosion resistance makes them suitable for plumbing and electrical work.

Automotive and Aerospace

Moreover, Their resistance to wear and high temperatures make them a preferred choice in automotive and aerospace industries.

Electronics

Also, their conductivity and durability make them suitable for connectors, switches, and housings.

Furniture and Industrial Machinery

Furthermore, in furniture for both functional and decorative purposes. In industrial machinery, they provide strong, reliable fastening for critical components

How to Choose the Right Brass Fastener

Purpose

Determine the specific application for the brass fasteners…

Consider Load and Strength Requirements

Based on the load and strength requirements of your application. Brass fasteners come in various grades and strengths, so choosing one that meets your specific needs is crucial.

- Select the Appropriate Alloy

Brass comes in different alloys with varying properties. For instance, naval brass has higher corrosion resistance due to its higher zinc content, making it suitable for marine environments.

- Choose the Right Size and Type

Select the correct size and type of fastener (like screws, bolts, nuts, or washers) based on your application requirements. Ensure that the dimensions and thread specifications match your design needs.

- Cost

There are many ways to manufacture fasteners, like forging, CNC Machining, casting, etc. Choose the appropriate way to suit your production and cost budget requests.

5. Surface Treatment

Some brass fasteners may undergo various surface treatments to meet the different application and performance requirements.

6. Standard and Certifications

Ensure that the selected fasteners comply with relevant industry standards…

7. Selection of Threading

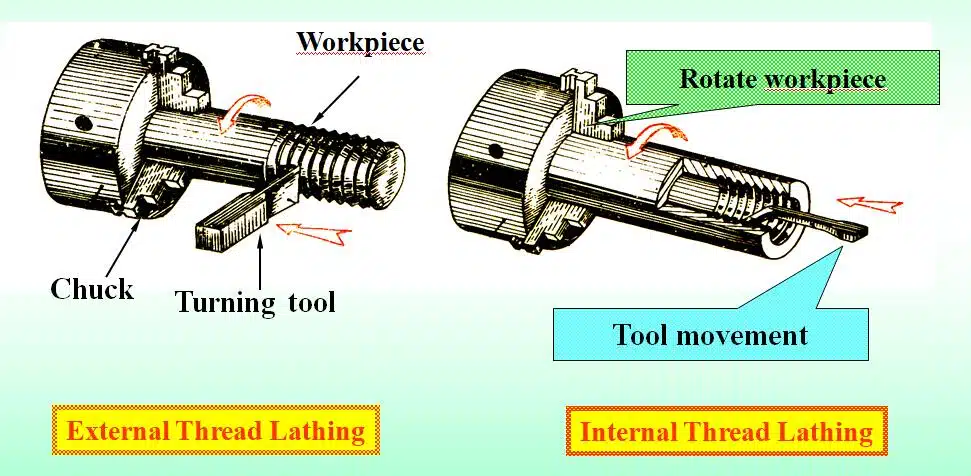

Threading is generally categorized into two main types: external and internal threading. Each type can be further divided into coarse and fine threads.

Thread Manufacturing

Threads are continuous protrusions or grooves found along a spiral line on a revolving component with the same cross sections.

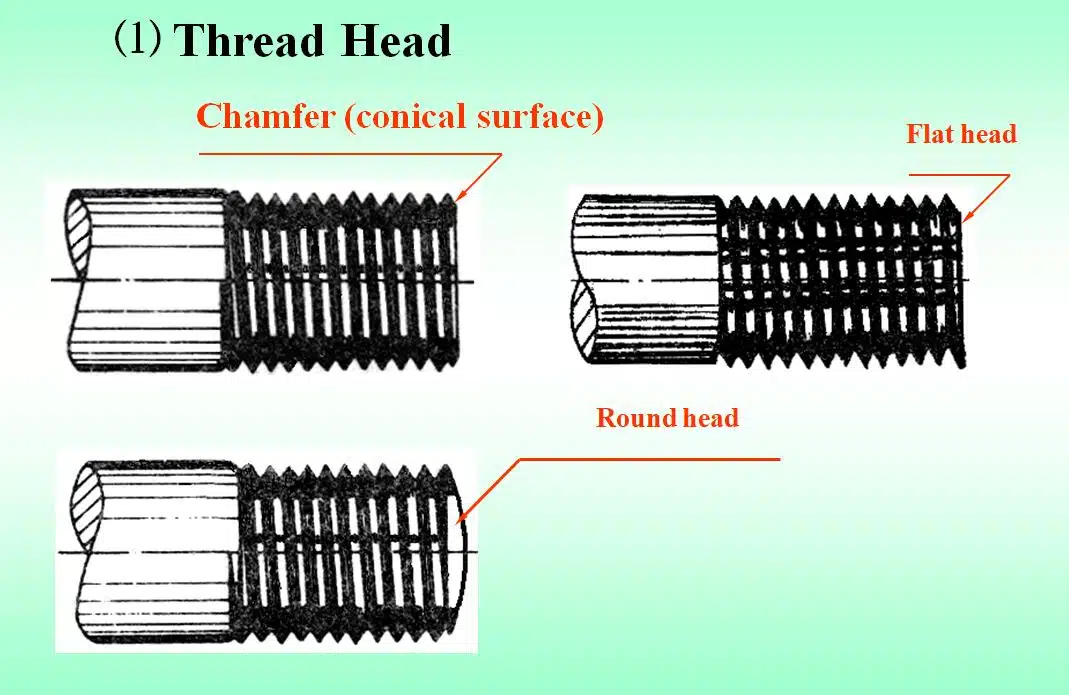

(1) Structure of the thread

(2) Thread runout and undercut

Thread runout: The incomplete segment at the end of the thread.

Undercut: A small groove at the end of the component, manufactured by CNC lathe.

(3) Thread element

(a) Tooth profile: The outline of the thread section cutting through the thread axis shows the thread tooth profile.

Typically types:

(b) Diameter: Including the major diameter (d,D), the minor diameter (d1, D1), and the pitch diameter ( d2, D2).

What is the process for brass fasteners?

- Cold Forging: Cold forging involves shaping brass at room temperature by pressing it into molds. Typically for mass production, providing strength and durability while being cost-effective for producing standard brass fasteners.

- CNC Milling: This technique uses rotating cutting tools precisely to remove material from a brass workpiece. An ideal process for creating complex and detailed designs, offering high precision and tailored for intricate brass fasteners.

- CNC Turning: In CNC turning, the brass workpiece is rotated against a stationary cutting tool to shape it. This process is suitable for producing precision parts with cylindrical shapes and achieves a smooth finish.

- Die Casting: This involves injecting molten brass into molds under high pressure. This technique is for high-volume production and complex shapes.

- Extrusion: Brass is forced through a die to create long sections of uniform cross-sectional shape. This process is used to produce fasteners with consistent profiles and is often followed by cutting to length.

- Hot Forging: Unlike cold forging, this method involves heating the brass before shaping it into molds. It is used for larger or more complex fasteners where increased material flow and reduced tool wear are beneficial.

Conclusion

Brass fasteners combine strength, durability, and aesthetic appeal, making them suitable for a wide range of applications. By understanding their types, advantages, and manufacturing processes, you can informed decisions and optimize their benefits in your projects.