Steels are broadly categorized as carbon steels, alloy steels, and stainless steels. 52100 is a high-carbon, chromium alloy steel. For applications that require high strength, excellent wear resistance, and the ability to withstand high hardness, 52100 steel is a suitable choice.

Key Facts

Material Type:High-carbon Chromium Alloy Steel

Hardness: Up to 66 HRC

Primary Features: Excellent Wear Resistance, High Fatigue Strength, Good Hardness

Common Applications: Bearings, Tooling, Knives

Machinability (Annealed): Fair (around 40-50% of a 1% carbon steel)

What Is 52100 Steel?

52100 steel belongs to the family of bearing steels, specifically designed to withstand repeated stress cycles and high contact loads. The SAE/AISI 52100 designation follows a systematic naming convention where the “5” indicates a chromium alloy steel, and the “100” represents approximately 1.00% carbon content.

This bearing steel is typically available in various forms to suit different manufacturing needs:

Forms: bar, tube, sheet, plate, ball bearing

Conditions: Annealed (softened for machining), pre-hardened (ready for final processing)

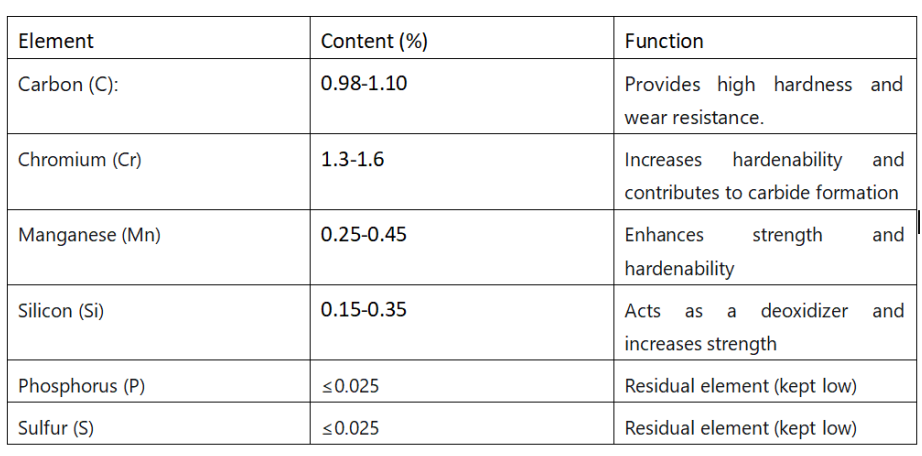

52100 Steel Chemical Composition

The exceptional properties of 52100 steel stem from its precise chemical formulation: It typically contains around 1.00% carbon and 1.50% chromium, with smaller amounts of manganese, silicon, and trace elements. This combination gives the steel its hardness and wear resistance.

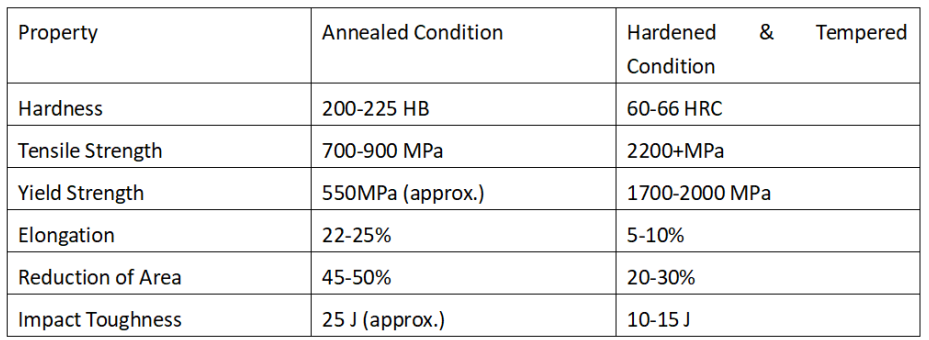

Mechanical Properties of 52100 Steel

The mechanical properties of 52100 steel vary significantly between annealed and hardened conditions: In the annealed state, it offers good machinability and moderate strength. In the hardened state, it achieves high hardness (up to 66 HRC), excellent wear resistance, and high fatigue strength, making it suitable for demanding applications.

Heat Treating of 52100 Bearing Steel

Proper heat treatment is crucial for unlocking 52100 bearing steel. Here’s a quick breakdown of the key stages:

✅ Annealing: Softens the material for optimal machinability before hardening.

🔥 Hardening (Quenching): The most critical step! A rapid transfer to the quench bath (within 3-5 seconds) is essential to achieve maximum hardness.

⚙️ Tempering: Follows quenching to reduce internal stresses and tailor the final hardness/toughness balance.

Proper execution at each stage ensures superior wear resistance, dimensional stability, and component life.

Machining and Welding 52100 Steel

Machinability

52100 steel presents moderate machining challenges, particularly in its annealed state:

Best Practices for Success:

- Tool Selection: Use sharp, positive-rake carbide tools

- Cutting Parameters: Moderate speeds with low feed rates

- Coolant: Use ample coolant to manage heat buildup

- Condition: Machine in an annealed condition whenever possible

- Tool Geometry: Optimized chipbreaker geometry recommended

Weldability

52100 steel has poor welding ability due to its high carbon content:

Primary Risks:

- High crack susceptibility in the heat-affected zone (HAZ)

- Formation of hard, brittle martensite

- Residual stresses leading to service failures

If Welding Is Absolutely Necessary:

- Pre-heat: 300-400°C (570-750°F)

- Electrodes: Low-hydrogen types (E7018, E10018)

- Post-weld: Immediate stress relief at 650°C (1200°F)

- Alternative: Consider brazing for joining applications

Applications of 52100 Steel

52100 steel excels in high-wear, high-precision applications:

Ball and Roller Bearings

The primary application where 52100’s high fatigue strength and wear resistance prevent spalling and extend service life is:

- Automotive wheel bearings

- Aircraft engine bearings

- Precision instrument bearings

- Industrial machinery bearings

Cutting Tools and Knives

- High-performance chef’s knives

- Hunting and tactical knives

- Industrial cutting blades

- Woodworking tools

Dies and Molds

- Forming dies

- Blanking punches

- Mold components for plastic injection

Specialized Components

- High-wear shafts and axles

- Precision instruments

- Gearing applications

- Automotive racing components

Advantages and Disadvantages of 52100 Steel

Advantages

- Superior Wear Resistance: Outstanding performance in abrasive environments

- High Contact Fatigue Strength: Excellent resistance to pitting and spalling

- Exceptional Hardness: Can achieve up to 66 HRC after proper heat treatment

- Excellent Dimensional Stability: Maintains precision after heat treatment

- Good Resistance to Plastic Deformation: Withstands heavy loads without permanent deformation

Disadvantages

- Poor Weldability: High risk of cracking requires specialized procedures

- Moderate Corrosion Resistance: Will rust if not properly protected

- Requires Expertise in Heat Treatment: Demands precise thermal processing

- Limited Toughness at High Hardness: Can be brittle in the hardened state

Other Steels vs. 52100

52100 vs. 4140 Steel

- 52100 Advantages: Superior wear resistance, higher hardness capability

- 4140 Advantages: Better toughness, superior weldability, lower cost

- Selection Guide: Choose 52100 for wear applications, 4140 for structural components

440C Stainless Steel vs. 52100

- 52100 Advantages: Slightly better wear resistance, higher purity versions available

- 440C Advantages: Far superior corrosion resistance, easier to obtain

- Selection Guide: 52100 for maximum wear performance, 440C for corrosive environments

52100 vs. O1 Tool Steel

- 52100 Advantages: Higher purity, better fatigue life, superior for bearings

- O1 Advantages: Easier heat treatment (oil-hardening), better dimensional stability

- Selection Guide: 52100 for high-cycle fatigue applications, O1 for tooling

Conclusion & Call to Action

52100 steel represents the pinnacle of performance for high-wear, high-precision applications. Its unique mix of high carbon and chromium makes a material that can handle extreme conditions. It also keeps its shape and has excellent wear resistance.

Whether you are designing high-speed bearings, precision tools, or strong parts, 52100 steel is a reliable choice. It offers proven performance that engineering and manufacturing teams can trust.

Need precision-machined components made from 52100 steel? AMSL manufacturing expertise ensures your parts meet the highest standards for performance and durability.

Submit your design today for a free, instant quote or Contact our engineering team to discuss how 52100 steel can solve your most challenging application requirements.

Let us help you leverage the exceptional properties of 52100 steel for your next project.